-

BOROSILICATE WAFERS

-

QUARTZ WAFERS

-

FUSED SILICA WAFERS

-

ALKALINE FREE WAFERS

-

SILICON-ON-GLASS WAFERS

-

CHEMICAL RELEASE CARRIER WAFER

-

THERMAL RELEASE CARRIER WAFER

-

LASER RELEASE CARRIER WAFER

-

MECHANICAL RELEASE CARRIER WAFER

-

ADAPTER WAFER & HANDLING TOOLS

-

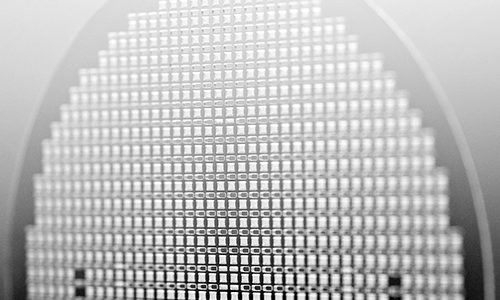

THROUGH HOLE WAFER

-

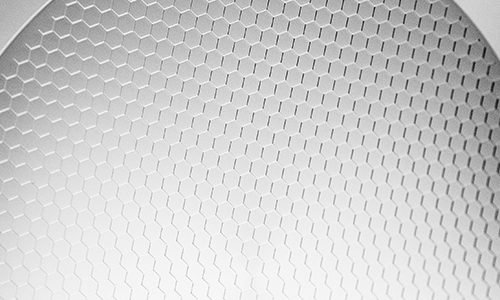

CAVITY WAFER

-

TRENCHED WAFER

-

CUSTOMIZED CAP SOLUTIONS

-

WAFERS WITH STRUCTURED SI-LAYER

-

GLASS INTERPOSER

-

SI INTERPOSER

-

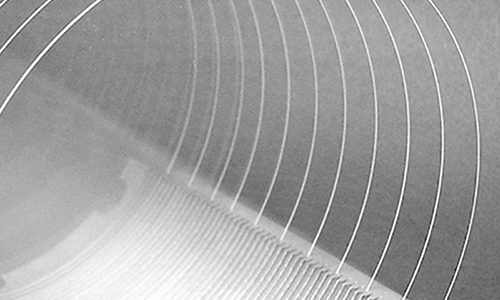

THROUGH GLASS VIAS (TGV)

-

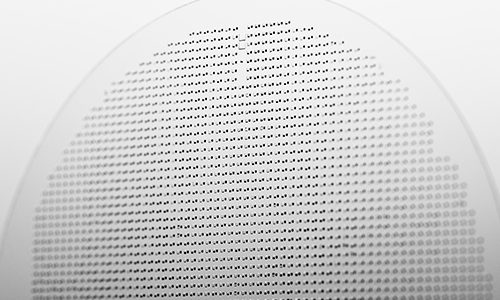

REDISTRIBUTION LAYERS

-

MICROREACTORS

-

FLUIDIC CHIPS

-

FLOW CHEMISTRY SETS

-

SENSORS

-

RAPID PROTOTYPING

-

VACUUM CASTING

-

INJECTION MOULDING

-

MECHANICAL PROCESSING

COPPER COATED GLASS WAFER AND CU-INTERPOSER

Plan Optik is the leading manufacturer of customized glass wafers! With it’s new “Advanced Conncectivity Technology (ACT)” Plan Optik developed a solution to create or refine products for 3D-Integration, 5G or other connectivity and high frequency applications.

In urgent need of stock products?

Wafer Universe offers a wide range of high-quality wafers from Glass and Quartz – available off the shelf. At Wafer Universe you will find a wide selection of various sized wafers and carriers in different diameters and thicknesses as well as materials, including Borosilicate Wafers (with regular or enhanced MDF polishing), Alkaline free glass wafers and Quartz wafers (semiconductor grade quartz). For more information please click on the logo.